Features of the KBK Flexible Double-Beam Suspension Crane

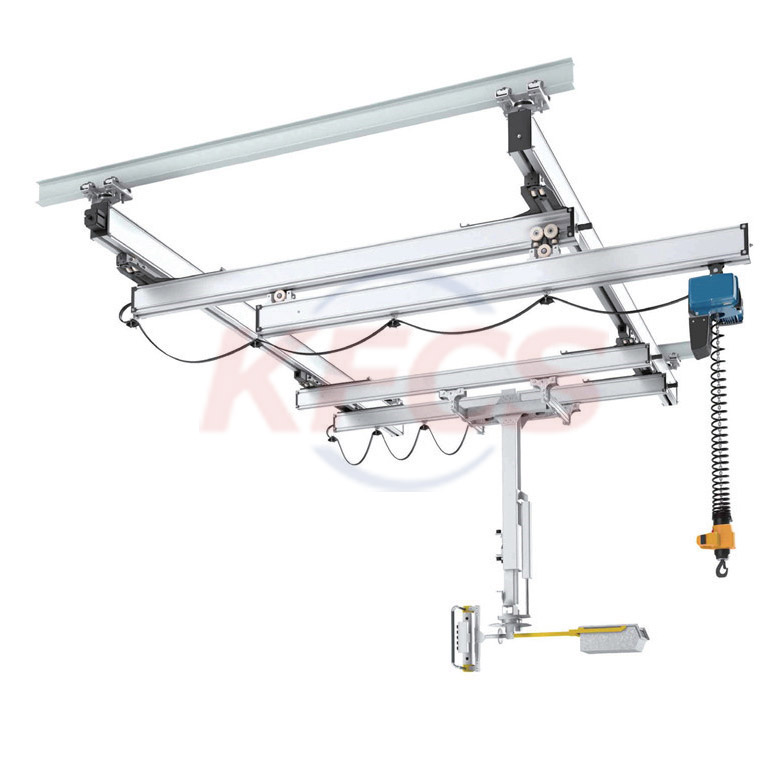

KBK flexible double-beam suspension crane is a modular and lightweight material handling equipment that can be directly suspended on the factory roof or the steel structure beam frame without complex foundation construction. It can realize efficient transportation of aerial materials through free combination and ready-to-use characteristics. Its load covers small and medium-sized scenes and is suitable for production lines, warehousing systems, and other environments with high space utilization and flexibility requirements. The core components include main beams, tracks, walking trolleys, electric hoists, mobile power supply devices, and control devices. This article will analyze its working principle, the double-beam structure advantage, and typical application scenarios.

What is a KBK flexible suspension crane?

KBK (German abbreviation of "Kombiniert Kran Baukastensystem") means "combined crane system" and is a modular suspension crane based on standard components. Its core components include:

• Suspension device: used to fix the crane system to the factory structure to ensure overall stability.

• Track system: using cold-rolled steel tracks, with high strength, good rigidity, and light weight, to support the smooth operation of trolleys and hoists.

• Traveling trolley: connects the electric hoist and the track, responsible for the lateral movement of the load.

• Electric hoist: realizes the lifting and lowering operation of the load, and the commonly used ones are chain-type and wire rope-type.

• Mobile power supply device: provides power support for the system to ensure the normal operation of each component.

• Control device: includes a manual controller and a remote control, which is convenient for operators to accurately control the crane.

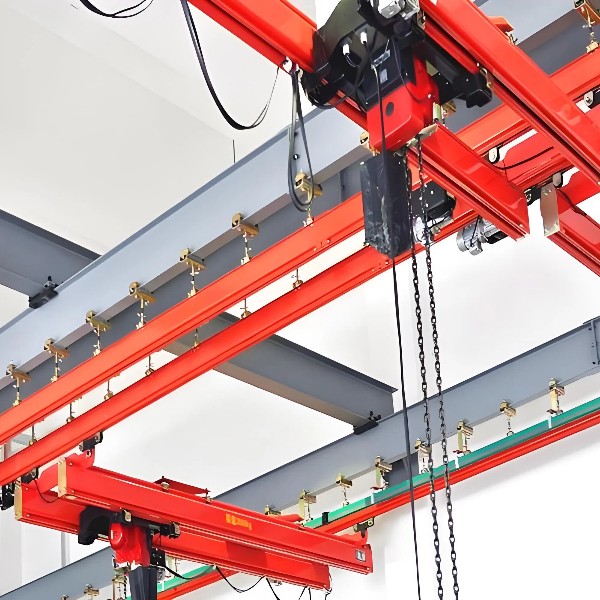

Core advantages of the double-girder structure

1. Higher load capacity and stability

The double-beam design evenly distributes the load to the two main beams. Compared with the single-beam structure, the bending strength is increased by more than 40%, which can adapt to the medium and heavy load requirements of 1t~2t;

The main beams are connected by cross braces to reduce shaking, which is especially suitable for long spans (≥8m) or high-frequency handling scenarios.

2. Stronger scalability

Supports the installation of multiple lifting devices on the main beam to achieve cross-regional synchronous lifting (such as parallel assembly of the body and chassis of the automobile production line);

The track length can be easily extended, or branch tracks can be added to build a circular and cross-type handling network.

3. Adapt to complex layouts

The double-beam spacing is adjustable, compatible with workpieces or equipment of different sizes (such as large molds, robot arm work area avoidance).

Optional end tools, such as rotating hangers and vacuum suction cups, can meet multi-angle handling needs.

4. Lower maintenance costs

When the modular components are damaged, they can be replaced individually without overall disassembly.

The double-beam structure reduces single-point stress fatigue and extends the life of the main beam to more than 10 years (ISO 4301 standard).

5. The lifting height is higher.

Because the hoist is suspended on the small frame between the two KBK main beams, the double-beam crane can provide higher lifting space than the single-beam crane.

Typical application scenarios

KBK flexible double-beam suspension cranes are widely used in the following fields:

• Automobile manufacturing: used for the handling and assembly of the engine, body, and other parts.

• Machining: suitable for the handling of various parts and components to improve production efficiency.

• Electronic assembly: meet the needs of high-precision, multi-station material handling.

• Warehousing logistics: realize efficient storage and transportation of goods.

• Food processing: suitable for material handling in clean environments to meet the hygiene requirements of the food industry.

Combined overhead crane provides highly flexible material handling solutions for modern industry through modular design, double-beam reinforced structure, and intelligent control technology. Whether it is lean production in automobile manufacturing or efficient sorting in warehousing logistics, its "on-demand construction and dynamic adjustment" characteristics can significantly optimize space utilization and operating efficiency. For small and medium-sized enterprises pursuing flexible production, investing in the KBK system is not only an equipment upgrade but also a key step towards intelligent and agile manufacturing.